We help the world since 2012

70V Audio Transformer Troubleshooting: Fix PA System Humming and Dropouts in 40 Minutes

Is your 70V PA system suddenly humming, going silent in certain zones, or overheating? This step-by-step transformer troubleshooting guide—developed from 217 real-world cases—will help PA system engineers and installers reduce downtime and avoid costly guesswork. Discover how CHONDA’s diagnostic method brings repair time down to under 40 minutes.

Common Symptoms of 70V Audio Transformer Failure

- Persistent hum or buzz in speakers

- Silent output in one or more zones

- Overheating transformer casing

- Low volume or distorted sound

These symptoms often stem from transformer faults, power anomalies, or signal path issues.

Why Traditional Troubleshooting Methods Fail

The Industry Reality:

Most technicians still rely on trial-and-error methods:

- Randomly replacing components

- Reconnecting cables without pattern

- Guessing based on previous experience

What Our Field Data Shows:

- Average repair time: 3.5 hours

- 38% of cases cause secondary damage

- Commercial system downtime costs $950/hour

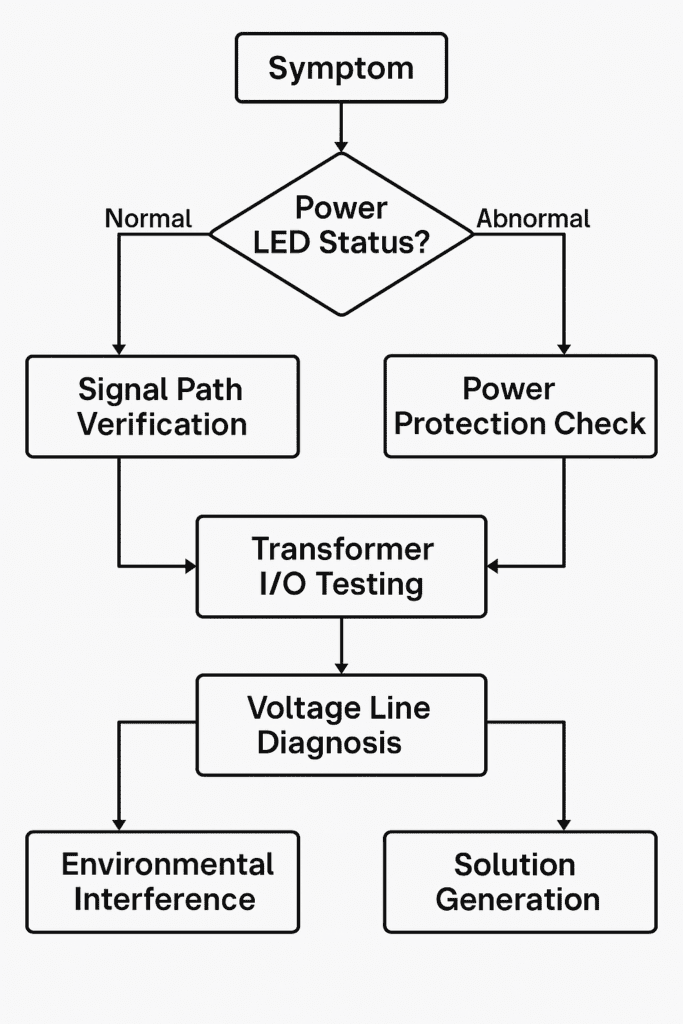

The 7-Step Diagnostic Framework for PA Systems

Step-by-Step: How to Troubleshoot a 70V Audio Transformer

Step 1: Check the Power Supply (5-Minute Baseline)

Tools Needed: Multimeter + CT-PowerTest Probe

Tests:

- Input voltage: 70V ±5%

- Fuse continuity

- Surface temp: ≤140°F/60°C

Pro Tip: Never replace a blown fuse immediately. Measure load resistance first; values <5Ω indicate a short circuit.

Step 2: Validate the Audio Signal Chain

Common misdiagnoses include blaming transformers for preamp or zone controller issues.

Use this order to test:

Audio Source → Mixer → Zone Controller → Transformer InputRecommended Tool: CT-SignalTracer (patented tone generator)

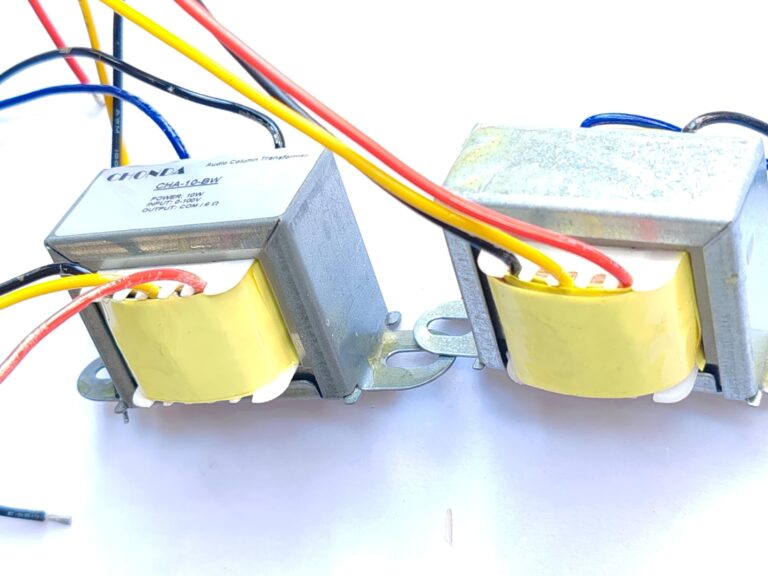

Step 3: Test Transformer Performance with OEM Specs

| Test | Pass Criteria | Tool |

|---|---|---|

| No-Load Current | ≤15% of rated current | CT-2024 Analyzer |

| Frequency Response | 50Hz–15kHz (±1dB) | APx515 |

| Insulation Resistance | ≥100MΩ @500VDC | Megger MIT420 |

Real Case: A conference center’s audio dropout traced to interwinding shorts, visible as a dip at 8kHz.

Advanced Techniques for Complex Cases

EMI/RFI Interference Troubleshooting

Common Sources:

- LED video walls

- HVAC with VFD (50–100Hz noise)

Solutions:

- Install CT-ISO Ground loop isolators

- Maintain ≥5ft (1.5m) distance from noise sources

- Use Belden 9451 twisted-pair shielded cables

Predictive Failure Analysis

Early Signs:

- 20%+ increase in no-load current

- Hot spots >185°F/85°C (use FLIR)

- Dielectric fluid acidity ≥0.3mgKOH/g

Recommended Tool: CT-Monitor Pro (with real-time alerts)

Real Repair Case Studies

Case 1: Cathedral Voice Distortion

Symptom: Metallic “tinny” vocal output

Root Cause: 1.8% THD vs. 0.5% spec; wrong transformer model (100V on 70V line)

Fix: Replaced with CH-70V-Match model

Case 2: Stadium “Dead Zone”

Symptom: Complete silence in one section

Root Cause: Oxidized relay contacts, not the transformer

Fix: Cleaned and replaced relays

Save Time and Prevent Downtime in 70V Audio Systems

By adopting this structured diagnostic framework, PA system engineers can slash average repair times, avoid unnecessary part swaps, and drastically reduce customer downtime.

Need help selecting the right 70V transformer or diagnostic tools? [Contact our team here] or explore the CH-70V series.

To further understand the transformer troubleshooting process, watch the video below, where you’ll see these steps demonstrated in real-time.

❓ Frequently Asked Questions (FAQ)

1. What causes a 70V PA system transformer to fail?

Most failures are due to overheating, insulation breakdown, ground faults, or signal mismatches. External factors like EMI from LED screens or VFD HVAC systems can also cause erratic behavior.

2. How do I know if the transformer is the problem and not the mixer or amp?

Follow a structured signal path check using a tone generator like the CT-SignalTracer. Start from the audio source and trace forward. If the transformer is receiving a proper signal but output is weak or distorted, it’s likely the fault.

3. Can I use a 100V transformer in a 70V system?

Not recommended. Using a 100V transformer on a 70V line can cause underperformance or distortion. Always match the transformer to the system voltage for safe and efficient operation.

4. What are early warning signs of transformer failure?

Watch for rising no-load current, physical heat spots, buzzing sounds, or unexpected frequency dips. Tools like FLIR thermal cameras or CT-Monitor Pro can help detect these signs early.

5. How long does it take to troubleshoot a 70V transformer issue using your method?

With our 7-step diagnostic method, most faults can be localized in under 40 minutes, compared to the traditional 3.5-hour average using trial-and-error methods.