We help the world since 2012

Powering Autonomous Mobile Robots (AMR): Optimized Solutions for Logistics and Service Industries

In the modern highly developed logistics and service industry, many companies and individuals enjoy the dividends, however one of the most pressing issues is the growing shortage of labor, which is seriously affecting manual labor positions, as well as those that require a higher level of skills and education.

Autonomous Mobile Robots (AMR) quietly entered the market in the midst of this challenge. AMR can autonomously navigate, avoid obstacles, and complete tasks such as handling and sorting, which has led to a significant increase in the operational efficiency of factories and warehouses, and logistics automation has soared under the drive of AMR.

With the continuous progress of technology, the application of AMR is not only limited to the industrial field, but also in the medical, hospitality and other service industries have been widely used.

AMR’s Specific Needs for Power Modules

With performance similar to that of a self-driving car, AMR is a complex design consisting of a series of subsystems that enable the robot to move, observe, and operate safely with as little human interaction as possible. To ensure the efficient operation of AMRs, the role of DC-DC Converter Module technology shipped is critical.

AMRs typically require long endurance and a stable current supply, especially in scenarios that require continuous operation. DC-DC Converter Module for AMRs need to fulfill several key requirements:

The power system and power components used in an AMR can have a significant impact on its total battery life and operating hours.

Important performance characteristics and parameters such as energy density, voltage and current requirements, efficiency, and solution size need to be considered when designing power systems for AMRs.

Long Duration

AMRs are often required to operate for long periods of time, especially in application scenarios where large-scale warehouses or round-the-clock operation is required. Therefore, the DC-DC Converter Module must support a high energy density design to ensure that enough energy can be stored in a small volume to extend the operating time of the AMR. High energy density reduces the charging frequency and increases the productivity of the AMR.

Stable current supply

In order to ensure that the robot continues to operate efficiently, the power supply module must be able to provide a stable voltage and current. the AMR’s mission often requires that the motor drive, sensor operation, and communication modules work continuously, which means that the power supply module needs to have the ability to respond quickly to avoid fluctuations in voltage or unstable current, and to prevent system failures or downtime due to power problems.

Efficiency

The energy efficiency of the power supply module directly affects the overall performance of the AMR. In order to reduce energy consumption, extend battery life and minimize heat buildup, power modules need to have the ability to convert at high efficiency. In particular, a higher efficiency DC-DC converter means fewer losses in the power transfer process, and thus a better ability to convert power into useful output. High-efficiency power modules can effectively reduce the burden on the battery, and help extend the AMR’s range and reduce overall operating costs.

Energy Density

AMRs are often limited by physical space, so the energy density of the power module is highly required. High Efficiency DC/DC Converters with high energy density can provide stronger power support in a limited space. This is especially important for small or compact AMRs that require long range. Choosing the right high energy density module not only reduces the charging frequency of the AMR, but also reduces the overall weight and improves the sports performance.

Voltage and Current Requirements

The AMR’s workload is often dynamic, so the DC-DC Power Supply Modules must have a wide range of voltage and current output capabilities. As the AMR performs different tasks, such as accelerating, decelerating, and lifting items, the current requirements will change over time. The power module needs to be able to provide sufficient voltage steadily, especially under high load tasks, to avoid voltage dips. At the same time, flexible voltage and current configurations can support the operational requirements of different AMR subsystems, such as motor drive systems, sensor systems, and control systems.

Program size

In order to accommodate the compact design of AMR, the size and volume of the power supply module is critical. A small power module not only helps optimize the internal space layout of the AMR, but also reserves more space for other functional components. Especially in high-density scenarios, the compactness of the power module can reduce the overall weight of the robot and improve its mobility. At the same time, smaller power modules are also easier to install and maintain, taking up less space and improving heat dissipation efficiency.

Advantages of CHONDA technology power modules for AMR applications

CHONDA technology’s DC-DC power modules perform well in AMR robots. Their efficient and stable power supply capability not only improves the efficiency of AMR, but also reduces equipment failures and improves overall performance:

Increased efficiency: Our power modules use advanced conversion technology to minimize energy loss and extend the AMR’s range, enabling it to perform tasks for longer without frequent recharging.

Reduced Failure: The power module’s high stability and anti-interference capability can maintain stable output during current fluctuations, reducing equipment failures and downtime caused by unstable voltage.

Strong adaptability: Whether it’s AMRs of different sizes or complex working environments, our power modules can flexibly adapt to various application scenarios and provide reliable power support.

Product Recommendations and Installation Suggestions

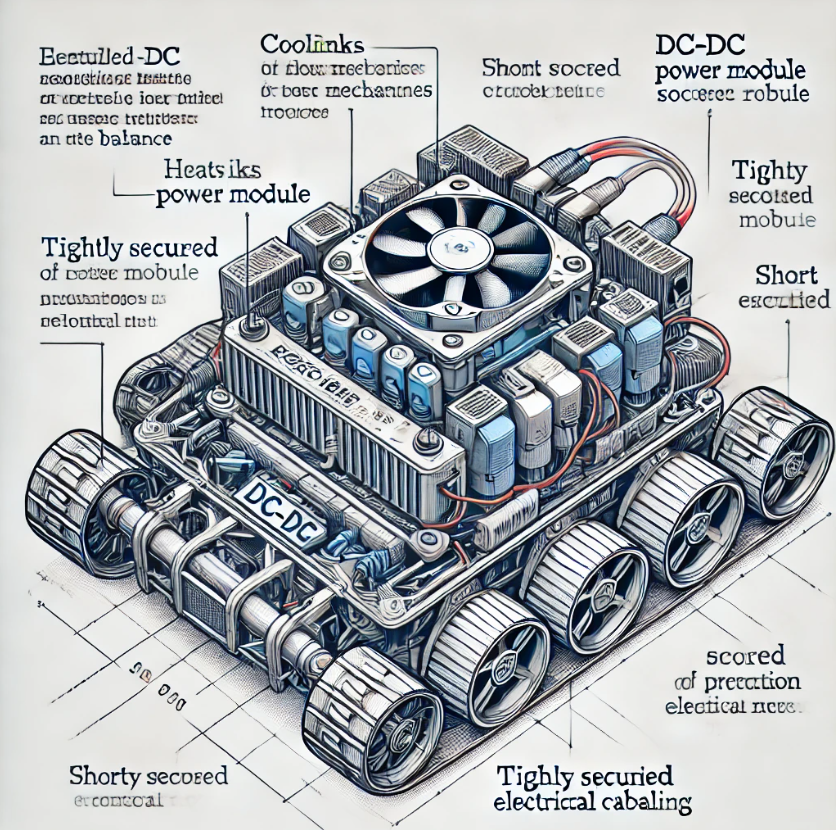

To ensure that AMR robots can perform at their best, we recommend using 50-150W DC-DC power modules, which have a high power density and are suitable for different types of AMRs. when installing the modules, we recommend placing them at the bottom of the AMR or at the back of the AMR in a space location to ensure good heat dissipation. At the same time, pay attention to the tightness of the cable connections to avoid loosening and power outages triggered by vibration. (see installation solutions diagram below)

Power Module Installation Suggestions

- Module Placement: To maintain the balance of the soccer robot, the power module can be installed at the center of the machine’s bottom. This helps to lower the center of gravity, improving the robot’s stability and agility.

- Thermal Design: The power module should have a good heat dissipation channel. You can use heat sinks or fans to ensure the power module doesn’t overheat during prolonged operation.

- Cable Connection: The cables of the power module should be as short and secure as possible to prevent them from loosening due to the movement of the soccer robot.

- Protection Design: If the soccer robot will be used outdoors or in humid environments, the power module should be sealed to prevent moisture and dust from entering.

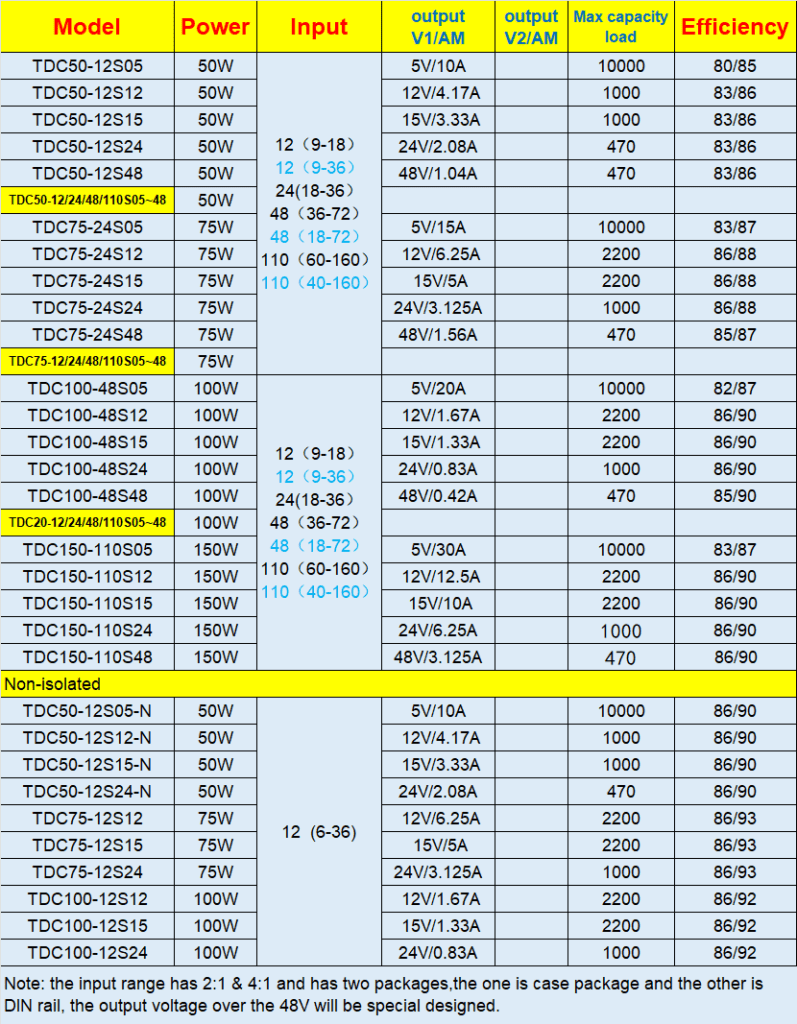

50-150W DC-DC power modules model list

Power solutions for footed robots: why DC-DC converters are the best choice?

Footed robots (e.g. service robots, patrol robots, etc.) have higher power requirements when performing tasks in complex terrain and harsh environments. Compared to AMR, foot-mounted robots require more stable and flexible power solutions.

Why is a DC-DC converter the best choice?

High efficiency: Footed robots require frequent speed changes and attitude adjustments, and DC-DC converters can quickly respond to changes in voltage demand to provide stable power support.

Flexible size: Our DC-DC converters have a compact design that allows them to be easily integrated into the tight spaces of footed robots without compromising their motion functions.

Durable: Our DC-DC converters are resistant to vibration and interference, making them ideal for use in environments where foot-based robots are in constant motion and change, ensuring stable long-term operation.

At CHONDATECH, we offer a range of products designed for efficiency and reliability since 2012. Our main offerings include:

- AC to DC Converters

- DC to DC Converters

- Transformers

- The other electrical components

These products are engineered with sleek designs and optimized performance, attracting attention and earning appreciation from users across various sectors. Whether for personal devices or industrial applications, CHONDATECH converters and inverters are widely used in a variety of systems requiring AC or DC power, such as mobile phones, laptops, audio devices, automotive lighting, and more.