We help the world since 2012

Potential Applications of High Voltage Power Modules in Robotics and Industrial Automation

With the rapid development of industrial automation and robotics, the performance and stability of power modules play a crucial role in equipment operation. For industrial robots with high-load tasks and long operating times, especially in high-voltage environments, traditional power supplies may not be able to meet these requirements. high voltage power module (HV power module) applications become the key to solving this problem. CHONDA TECHNOLOGY will explore some aspects according to the market.

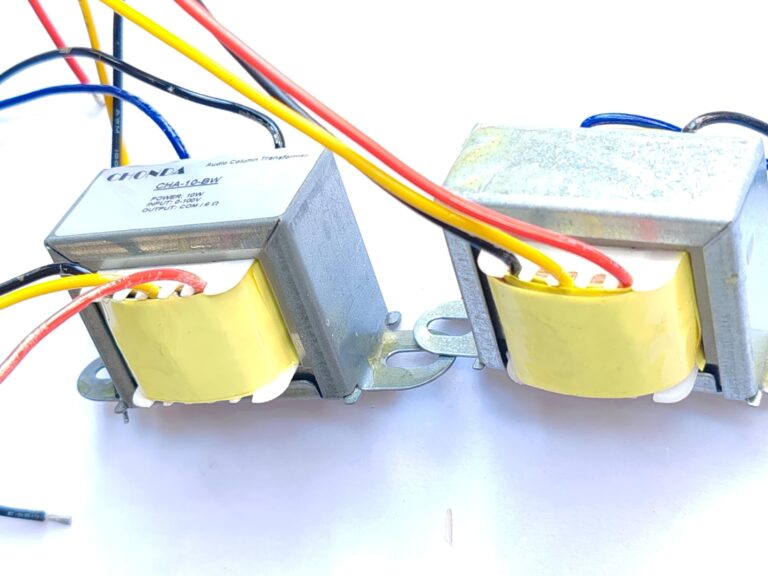

Advantages of high voltage power modules

1000V power modules are particularly suited to the complex operating environments of robots and automation equipment due to their ability to provide stable current at high voltage. Compared to low-voltage power supplies, high-voltage power modules are able to provide greater power output for high-load tasks while maintaining energy efficiency, which gives them a significant advantage in industrial automation.

Three Mainly features of the high-voltage power modules

High efficiency: high-frequency switching technology is adopted in the high-voltage module power supply, which makes the conversion efficiency of electric energy up to more than 90% and greatly reduces the energy loss.

Stability: due to the use of advanced control technology and high-quality components, the high-voltage module power supply has excellent stability and reliability, and is able to work normally in a variety of harsh environments.

Compactness: High-voltage modular power supply adopts modular design, small volume and light weight, easy to integrate and install.

High-voltage power module not only has all the performance of the power module and its performance requirements are higher, for high-voltage power and high-current switching to reduce losses, but also has a strong isolation and anti-interference, can play a role in protecting the integrated board on the role of the various small integrators to facilitate integration.

In robotic systems, high-voltage power modules increase the efficiency of the robot and reduce the energy loss caused by frequent power transitions. This is especially important for equipment that needs to work without interruption for long periods of time. Whether on production lines operated by heavy machinery or in automation equipment working remotely, high-voltage power modules ensure stability and continuous operation over long periods of time.

Potential applications in robotics and industrial automation

Although the use of photovoltaic power modules in robotics is not yet widespread, the potential is enormous, especially in the field of industrial automation power modules. We can imagine several typical potential application scenarios:

Drones and patrol robots: Drones and patrol robots operating outdoors often require long periods of autonomous operation. Using photovoltaic power modules, these robots can be recharged by solar energy during the day, reducing their dependence on traditional power sources and greatly improving their endurance. In these scenarios, 1000V high-voltage power modules can provide strong and continuous power support for the equipment.

Industrial automation production lines: High-voltage power modules are particularly suitable for industrial automation equipment with high energy consumption. For example, large-scale production equipment requires stable high-power output to ensure continuous operation, and high voltage power modules can provide efficient energy solutions for such equipment. Especially in production lines with high energy consumption, PV power modules are expected to be the ideal choice for energy saving and environmental protection.

Remote monitoring and probing robots: For monitoring robots that need to operate in harsh environments for long periods of time, the safety and reliability of high voltage power modules are crucial. With photovoltaic power generation, these devices can remain autonomous for long periods of time in the field or in difficult-to-maintain locations, reducing the need for human intervention.

Safety design of high-voltage power modules

In high voltage environments, the safety design of the device is a critical element that cannot be ignored in any robotic power solutions. High voltage power modules need to be designed with insulation, overload protection and temperature control in mind to ensure the stability of the equipment during long periods of high load operation. The company’s products excel in this area and maintain excellent performance in harsh industrial environments.

CHONDA INTERNATIONAL TECHNOLOGY CO., LTD is a leading global company specializing in power converters. Our mission is to make a significant impact on the market, establishing CHONDATECH as a trusted brand recognized for innovation and reliability. We focus on developing advanced power regulation technologies, particularly for the Military and Medical industries, where precision and performance are crucial. CHONDATECH prioritizes high quality, affordability, and excellence by utilizing modern, cutting-edge components to create products that are both reliable and efficient.