We help the world since 2012

New Thinking in Toroidal Transformer Installation

- When Standard Parts Meet Non-Standard Requirements

- Five Common Installation Misconceptions

- CHONDA’s Four-Step Customized Installation Process

- CHONDA’s Game-Changing Customization Success Stories

- Affordable Customization for DIY Enthusiasts

- Simplified Installation Guidance: Like Tailored Shoes for Your Equipment

- Are You Settling for a Standard Transformer?

- “Perfect Fit” in Transformer Installation

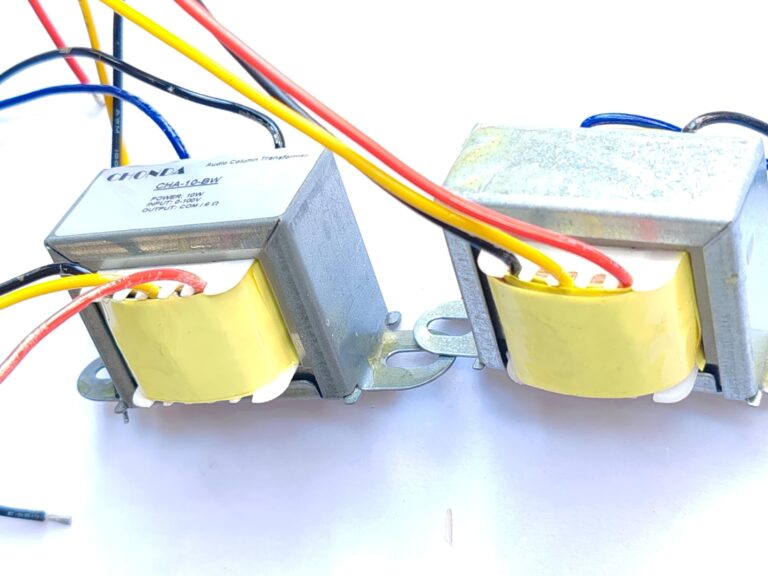

When Standard Parts Meet Non-Standard Requirements

In the industrial sector, 90% of equipment failures arise from using standard transformers in non-standard applications. CHONDA’s philosophy is simple: There are no unsuitable working conditions—only mismatched transformers. We don’t create the most expensive toroidal transformers; we create the most suitable customized solutions tailored to your needs.

Five Common Installation Misconceptions

1. Just Matching Power to the Load

Misconception: Simply choosing a transformer with power close to the required load ensures proper operation.

Case Study: A food processing plant used a standard 800W transformer for refrigeration equipment, which burned out after three months of continuous overload.

CHONDA Solution: A custom design with 130% instantaneous overload capacity, preventing future failures.

2. Underestimating Space Constraints

Real Scenario: An audio studio had to modify cabinets because the transformer thickness exceeded available space.

CHONDA’s Fix: Flat-designed transformers as thin as 35mm to fit seamlessly.

3. Ignoring Connector Quality

Typical Issue: Mining equipment experienced terminal loosening due to vibrations.

CHONDA’s Fix: Military-grade plug connectors with anti-vibration potting technology for enhanced durability.

CHONDA’s Four-Step Customized Installation Process

Step 1: Comprehensive Working Condition Diagnosis (Free Service)

We provide a “Transformer Requirement Diagnosis Table” covering:

- Operating Hours: Less than 8h or 24h continuous?

- Humidity Levels: Below 60% or extreme conditions like offshore/mining?

- Load Characteristics: Constant or fluctuating?

Step 2: 3D Customization for Seamless Integration

Case Study: An elevator manufacturer required a customized mounting solution.

CHONDA Customization: Integrated mounting tabs, eliminating additional machining.

Step 3: Test-Fit Services

- White mold verification (non-metal sample prototypes)

- On-site simulation installation support

Step 4: Lifetime Adaptation Commitment

- Upgrade-friendly: Old units can be restructured and rewound when upgrading equipment.

- Free reinstallation adjustments for size modifications.

CHONDA’s Game-Changing Customization Success Stories

Case 1: Award-Winning Hidden Transformer in a Coffee Machine

Challenge: Fitting a 150W transformer within a 5cm space constraint.

Solution: A hybrid toroidal + PCB structure.

Result: The customer won the Red Dot Design Award. (Source)

Case 2: Antarctic Research Station’s Extreme Cold Adaptation

Challenge: Conventional transformers failed in -60°C conditions.

Customization: Silicone oil impregnation + specialized magnetic core.

Effect: Uninterrupted operation for over 3 years. (Learn More About Extreme Environment Solutions)

Affordable Customization for DIY Enthusiasts

Small-Batch Customization (Starting at Just 5 Units!)

- Exclusive Student Project Support: Assisting with graduation design projects.

- Creator Discounts: Custom transformers for open-source hardware projects.

Modular Customization Menu

- Basic Accuracy (±10%) → High Precision (±1%)

- Standard Black Color → Personalized Custom Painting

- Standard Leads → High-Temperature Silicone Leads

Simplified Installation Guidance: Like Tailored Shoes for Your Equipment

Standard transformers are like off-the-shelf shoes—sometimes they fit, but often they don’t. CHONDA customization is like a master shoemaker:

- Measurement (Condition Checking)

- Material Selection (Transformer Core & Winding Customization)

- Prototype Testing (White Mold Verification)

- Lifetime Fit Guarantee (Adjustments as Needed)

Are You Settling for a Standard Transformer?

✔ Yes, it’s barely working.

✔ No, I need a customized solution!

Get Your Free Customization Assessment Today!

📞 Call Our Customization Hotline: +86 15997943380

🛠️ Or Visit: www.chondatechnology.com

“Perfect Fit” in Transformer Installation

At CHONDA, we believe:

“The best installation is not just placing a transformer into a machine—it’s integrating it seamlessly into the machine’s lifecycle.”

🚀 Looking for a hassle-free toroidal transformer installation?

✅ CHONDA’s custom solutions ensure the perfect fit for your needs.

📩 Get a free consultation today!