We help the world since 2012

Essential Factors for Choosing Power Supplies in Robotics

The Importance of Choosing Power Supplies in Robotics

In today’s fast-evolving field of robotics, selecting the right power supply is essential for optimal performance and effective applications. From industrial and service to medical robots, the power supply influences not only overall functionality but also efficiency, safety, and equipment longevity. Understanding the core factors for choosing power supplies in robotics helps you make a well-informed decision.

- The Importance of Choosing Power Supplies in Robotics

- 1. Key Selection Factors: Power Requirements, Size, and Efficiency

- 2. Power Supply Types: Linear and Switching Power Supplies

- 3. Environmental Adaptability: Temperature, Humidity, and Interference Immunity

- 4. Safety and Certification

- 6. Application-Specific Requirements

- Conclusion: Selecting the Right Power Supply for Robotics

1. Key Selection Factors: Power Requirements, Size, and Efficiency

Power Requirements

Power requirements vary based on robotic applications. Industrial robots generally demand higher power for complex tasks and extended runtime, while service robots may require lower power for energy efficiency and extended operation. Ensuring the power supply meets these requirements is crucial for stable, efficient operation.

Size

Power supply size is critical in robotic systems where space is limited. Compact, high-density power supply modules save space and increase modularity, allowing for better motion control and stability in robotic applications.

Efficiency

Power efficiency directly impacts robot power consumption. High-efficiency power supplies reduce heat generation, extend battery life, and decrease dependency on cooling, lowering overall operating costs. Prioritize power supplies with high power efficiency—especially for robotic applications with higher energy demands.

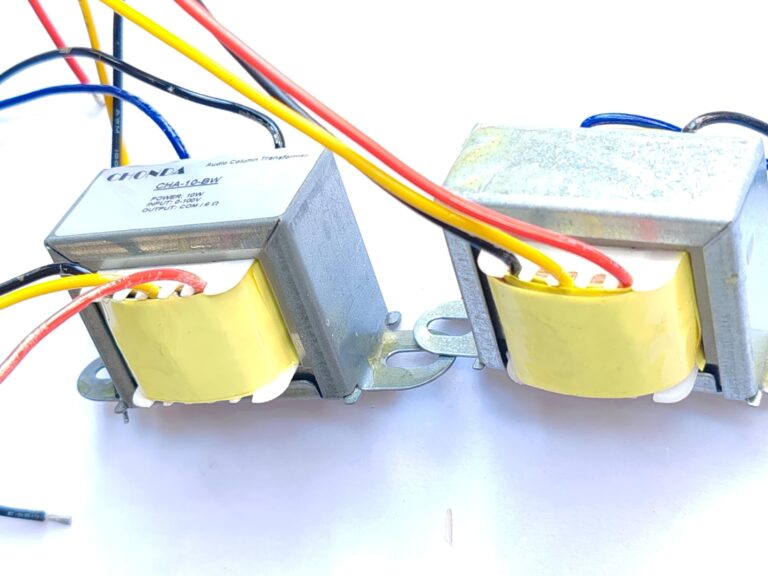

2. Power Supply Types: Linear and Switching Power Supplies

In robotics, linear power supplies and switching power supplies are two common types, each suited to different needs.

Linear Power Supplies

Linear power supplies offer a steady DC current, which results in low electromagnetic interference and very stable output. However, they tend to have lower efficiency due to heat production. They work best in scenarios requiring minimal noise and stable output, such as medical robots or precise lab equipment.

Switching Power Supplies

Switching power supplies use high-speed circuits, providing high efficiency and power density in smaller sizes. Although they may create electromagnetic interference, they’re well-suited for service robots and industrial robots that prioritize efficiency and compact size.

Choosing the Right Type: Linear power supplies work best in settings requiring low noise and stability, while switching power supplies excel in high-efficiency, space-conscious robotic applications.

3. Environmental Adaptability: Temperature, Humidity, and Interference Immunity

Environmental adaptability is a key factor when choosing power supplies in robotics. Robots may operate across varying conditions, so power supplies should provide adequate temperature and humidity resistance.

Temperature and Humidity

The right power supply enhances robot stability and longevity, even in extreme environments. High or low temperatures impact power supply efficiency, potentially leading to overheating or performance drops. Likewise, humidity can corrode circuitry, so moisture-resistant power supplies are recommended. For example, IP65-rated power supplies are dustproof and splash-resistant, while IP67 provides greater protection for outdoor or underwater robotic applications.

Anti-Interference Capability

In environments with high electromagnetic interference (EMI), the robot’s power supply should ensure smooth operation. EMI-resistant power supplies with robust shielding and filtering help maintain stability in complex environments. Power supplies meeting electromagnetic compatibility (EMC) standards reduce interference risks, ensuring reliable robot performance.

4. Safety and Certification

Safety standards and certifications guarantee the reliability of power supplies in robotics. Common certifications include UL for fire and electrical safety in the U.S. and CE for EU compliance. Specialized applications may require IEC, RoHS, or FCC certifications, particularly in medical and industrial robotics.

Achieving these certifications confirms that power supplies meet strict quality standards, reduce safety hazards, and support robotic applications that prioritize safety and reliability.

5. Cost-Benefit Analysis: Initial Investment vs. Long-Term Operating Costs

Consider both initial investment and long-term operating costs when choosing power supplies in robotics. Linear power supplies have a lower upfront cost but higher operational costs due to lower efficiency. Switching power supplies, although more expensive initially, offer higher power efficiency, leading to reduced energy and cooling costs. In long-term robotic applications, the cost savings from high-efficiency power supplies can far exceed the initial investment.

6. Application-Specific Requirements

- Industrial Robots: Often used in high-load tasks, industrial robots require power supplies with high stability and durability. In manufacturing, continuous power output is essential to maintain production line continuity.

- Service Robots: Emphasize energy efficiency and low weight, as service robots (e.g., delivery or housekeeping) frequently switch between standby and active modes. A power supply with fast response and high efficiency is ideal.

- Medical Robots: Precision and stability are paramount in medical robots used in surgeries and rehabilitation. These robots require stable voltage and anti-electromagnetic interference to ensure patient safety.

Conclusion: Selecting the Right Power Supply for Robotics

Choosing power supplies in robotics requires careful evaluation of power demand, size, and efficiency. Industrial robots prioritize stability, service robots focus on efficiency, and medical robots require precision. The right power supply enhances robot performance and extends equipment lifespan, laying the groundwork for robotic applications in diverse fields.