We help the world since 2012

Choosing the Right Power Module for AGVs: TDC50-12S24 Power Module Workflow Analysis

Following the previous blog post, “How to choose an efficient DC/DC power module for AGVs?”, this article will take the TDC50-12S24 dc dc power module as an example to explain how this modular power supply is applied to Automated Guided Vehicles (AGVs) robot equipment. Vehicles (AGVs) robot equipment.

First understand the benefits of AGVs

AGVs offer many benefits in the manufacturing and warehousing industries, such as:

Increased efficiency and productivity.

AGVs increase productivity and efficiency and are predictable and reliable for routine tasks, due to their autonomous operation. AGVs eliminate unnecessary walking and the physical labor associated with moving materials. AGVs guide employees through each task, minimizing human error, which improves order picking accuracy and reduces product loss and misalignment.

Stabilized costs.

Because AGVs are typically purchased on a per-unit or lease term basis, costs are less variable than labor, which can vary based on market conditions and demand.

Flexibility.

Compared to other AGVs, some AGVs require the re-routing of guide lines or other infrastructure to adjust the vehicle’s route, while some AGVs have the flexibility to change routes. Automated guided vehicles are scalable because they can be expanded as needed.

Less space is required.

AGVs take up less space than other automation solutions such as conveyor systems. Some AGVs are more compact than forklifts and other traditional warehouse machinery, allowing floor plans to utilize available space more efficiently.

Improved Safety.

Finally, AGVs are a safe automation solution for manufacturing facilities, distribution centers and warehouses.AGVs have sensors to help them avoid collisions. Advanced AGVs such as AMRs can plan the most efficient route through a warehouse or facility, reducing aisle congestion and the risk of accidents.

TDC50-12S24 DC DC Converter Module Overview

- Installation method of the machine shell

- Installation with guide rail

- Efficiency up to 90%

- Maximum output power of 150W

- Operating temperature range: -40℃ to +85℃

- No-load power consumption, low radiation interference, ripple noise less than 1%Vo

- High isolation withstand voltage of 1500V DC or 800V AC

- Certified and designed to be environmentally friendly, compliant with RoHS directive.

The TDC Robotics DC-DC Power Modules feature isolated and regulated single-output with an efficiency of up to 90%. These modules offer a high isolation voltage of 1500VDC and can operate in a wide temperature range from -40℃ to +85℃.

Additionally, they include input undervoltage protection, as well as output overvoltage, overcurrent, and short circuit protection. Widely used in robotics, drones, railway equipment, medical devices, industrial control, power systems, and telecommunications, these DC-DC power modules ensure reliable performance in demanding applications.

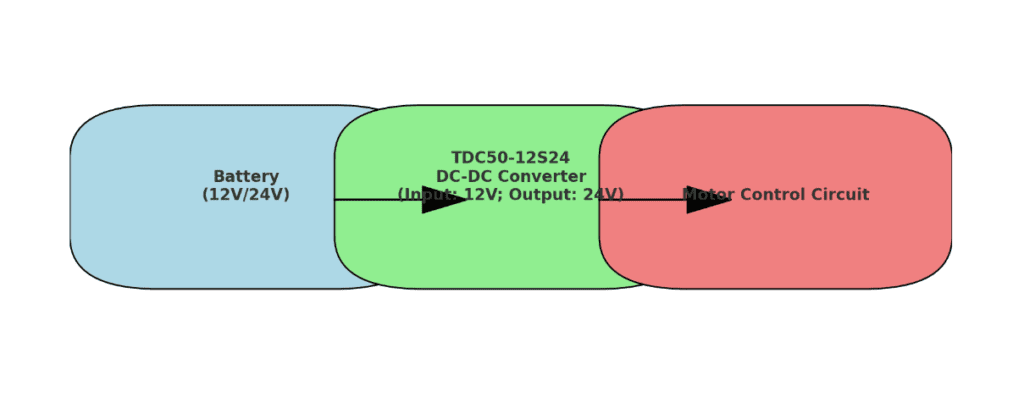

DC DC Power Supply Module Workflow Analysis

Battery: Serves as the starting point for the power supply, providing 12V or 24V input.

DC-DC converter (TDC50-12S24): Converts the battery voltage to the required 24V, supporting an output of 2.08A to ensure the stability of the motor control circuit.

Motor control circuit: utilizes the converted voltage to drive the movement of the AGV.

Advantages of the DC DC power supply module

1. High efficiency and stability

The high efficiency design of this module power supply, TDC50-12S24, performs well under different load conditions, and the efficiency usually reaches more than 90%. This means that during operation, the AGV can maximize the use of input power, reduce energy loss and extend battery life.

At the same time, the module provides stable output voltage and current, ensuring no fluctuations when the load changes. This stability is crucial to the normal operation of the AGV, which can effectively avoid performance degradation or system failure caused by unstable power, thus enhancing the reliability of the entire automated logistics system.

2. Compact design

The compact design of the TDC50-12S24 DC DC modular power supply makes it ideal for AGV systems with limited space.

Since AGVs are usually operated in small environments with limited internal space, choosing a compact power supply module leaves more room for other important components, such as controllers, sensors and drive motors.

In addition, the compact design not only reduces the overall weight of the AGV, but also makes the integration and installation process easier, thus increasing productivity.

3. Adaptable to a wide range of input voltages

The TDC50-12S24 power supply module’s ability to adapt to a wide range of input voltages (e.g., input range 9-18V or 9-36V) provides AGVs with great flexibility. The modules work reliably whether they are drawing power from different sources or battery packs, or are used in a variety of operating environments.

This adaptability allows the AGV to easily cope with different charging equipment or power conditions, ensuring continuous operation and reducing the overall complexity of the system.

Real-world user feedback

Customer Background

“XX Logistics has deployed a series of Automated Guided Vehicles (AGVs) in its warehouses for automated transportation and handling of goods.

In order to improve the reliability and efficiency of the system, they decided to use TDC50-12S24 DC-DC converters in their AGVs.

Performance: XX Logistics has significantly improved the efficiency of its AGVs after applying the TDC50-12S24. The module’s high efficiency and stable output ensures that the AGVs can continue to operate under different workloads, reducing downtime due to power problems. the AGVs’ operating frequency has increased by about 20%, and the power loss during operation has been reduced, resulting in a noticeable improvement in the range of the entire vehicle.

User Feedback

Mr. Wang, Equipment Engineer: “We are very satisfied with the performance of the TDC50-12S24. Its high efficiency has allowed us to optimize our energy use, especially during long working hours, and the battery life of the AGV has been significantly increased.”

Ms. Li, Operations Manager: “Since using the TDC50-12S24, we have seen a significant reduction in our failure rate, with almost no breakdowns due to unstable power supply. This has made our workflow smoother and the workload of our employees lighter.”

Mr. Zhang, R&D Supervisor: “The compact design of the module is perfect for our AGV system, allowing us to configure it more efficiently in a limited space. At the same time, the wide range of input voltage adaptability allows us to easily cope with different power conditions, and simplifies equipment maintenance.”

We hope the above process work on the application of TDC50-12S24 power supply module in AGV can be useful for you!

CHONDA INTERNATIONAL TECHNOLOGY CO., LTD is a leading global company specializing in power converters. Our mission is to make a significant impact on the market, establishing CHONDATECH as a trusted brand recognized for innovation and reliability. We focus on developing advanced power regulation technologies, particularly for the Military and Medical industries, where precision and performance are crucial. CHONDATECH prioritizes high quality, affordability, and excellence by utilizing modern, cutting-edge components to create products that are both reliable and efficient.