We help the world since 2012

Power Supply in Robotics: Ensuring Reliability for Optimal Performance

In the rapidly evolving world of robotics, having a dependable power supply is essential. Whether in industrial, commercial, or home robotics, power reliability and stability are crucial for optimal performance.

This article explores the key role of power supplies in robotics, the importance of reliability, and the technologies that enhance performance.

1. Understanding Robotics Power Supplies

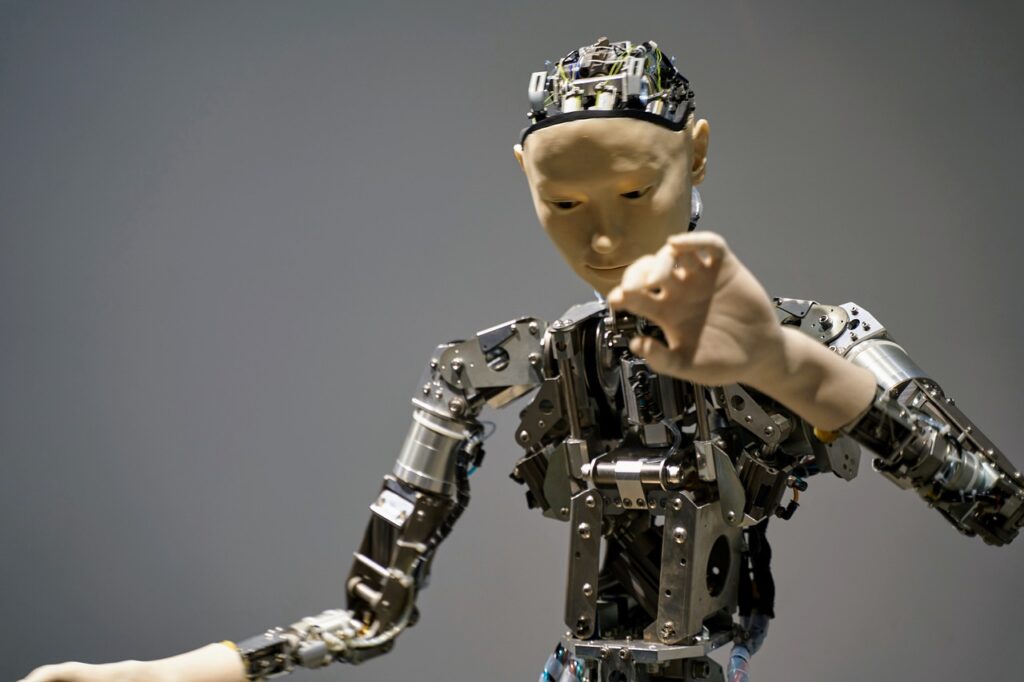

First, let’s define what a robot power supply is. It serves as the core component that powers the robot. A stable power system ensures smooth operations. Key components include power modules, controllers, and sensors. These elements play a vital role in the overall system.

Commonly, a robot power supply uses electronic switching devices. These include transistors and thyristors. By controlling these devices, the power supply can pulse modulate the input voltage. This process allows for DC/AC and DC/DC voltage conversion, as well as adjustable output voltage and stabilization.

2. The Importance of Reliability

Next, let’s discuss why reliability is so crucial. A robotic system is complex. It consists of precision components such as motors, sensors, and controllers. These components require stable and continuous power. Power fluctuations can lead to performance degradation and downtime. This disruption can cause workflow interruptions and added costs.

Benefits of Reliability

Here are three key benefits of having a reliable power supply:

- Operational consistency: Robots perform repetitive and precise actions. Even minor power fluctuations can disrupt these actions.

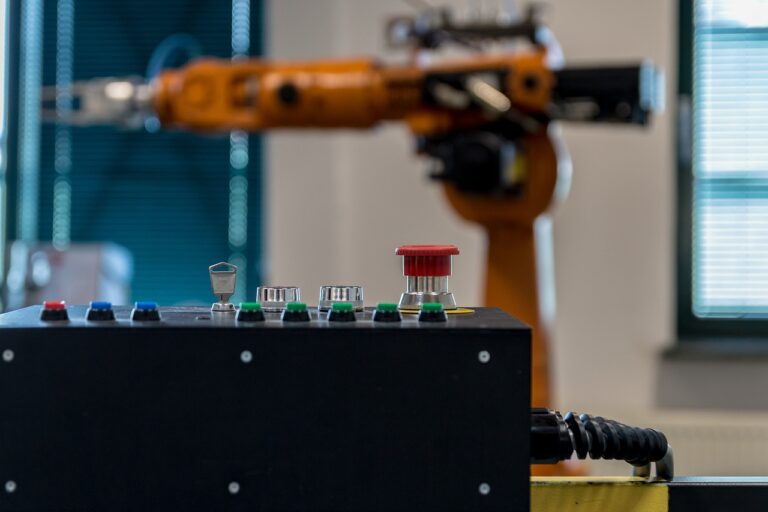

- Safety hazards: In industrial settings, unexpected power issues can cause machinery to stop, posing risks to operators and equipment.

- Extended lifespan: A stable, high-quality power supply prevents wear and tear on components, extending the robot’s working life.

3. Characteristics of a Power Supply in Robotics

When selecting a power supply for robots, consider these features to enhance reliability:

- Voltage regulation: A stable output voltage is critical. It reduces the risk of failure by ensuring that the robot receives consistent power.

- Overload protection: Power supplies with built-in overload protection shield critical components from damage caused by current surges.

- Thermal management: High-performance robotic applications generate heat. Quality power supplies often have thermal mechanisms to cope with high loads.

- Compact and rugged design: Power supplies must withstand harsh environments, including vibration and extreme temperatures, without compromising performance.

4. The Role of Power Stability

A stable power supply is essential for high efficiency and performance in robotic applications. Power stability impacts functionality and consistency:

- Sensor accuracy: Robots rely on sensors for navigation and object detection. Stable power enhances sensor accuracy.

- Continuous operation: Robots often operate 24/7. Stable power prevents unplanned downtime and maintains productivity.

- Battery management for mobile robots: In mobile or battery-powered robots, power management is critical. An efficient power supply can help keep robots fully charged during long operation hours.

5. Innovations in Power Supply Technology

Several innovations enhance the robustness and efficiency of power supplies for robots:

- Intelligent power supplies: Equipped with diagnostic tools, these supplies can adjust output based on real-time demand, optimizing efficiency.

- Energy harvesting technologies: Some robotic systems utilize ambient energy sources, like solar, to supplement power needs. This increases reliability and reduces reliance on a single source.

- Regenerative power systems: In robots using regenerative braking, the power supply recovers energy that would otherwise be wasted, improving overall efficiency.

6. Choosing the Right Power Supply

When selecting a power supply, consider the specific needs of the robotic system. Industrial robots typically need durable power supplies with high voltage stability. In contrast, mobile or small robots may require compact, lightweight options.

Examples of Power Supply in Robotics

- DC-DC converters: These are suitable for low-voltage robots and provide stable output despite load variations.

- AC-DC converters: Typically used for larger robot applications, these converters offer reliable power with high efficiency.

7. Frequently Asked Questions (FAQ)

How do I choose the right power supply for my robot?

When choosing the right power supply, consider the robot’s power requirements, voltage needs, and operating environment. Ensuring that the power supply module meets these requirements is crucial.

What are the main factors that affect robot reliability?

Key factors include unstable power supplies, component wear, environmental conditions, software errors, and lack of regular maintenance.

How can I improve the power stability of my robotic system?

You can improve power supply stability by using efficient DC-DC converters, implementing a robust battery management system, and maintaining power supply components.

What is a DC-DC converter?

A DC-DC converter changes DC voltage to a different level. It is used in robots to provide the required voltage for various components and sensors.

How can I monitor my robot’s power performance?

You can track the power supply performance by installing a monitoring system. This system provides data on voltage, current, and temperature, helping identify potential issues.

How important is regular maintenance for robot power supplies?

Regular maintenance is critical for ensuring reliability. It helps identify and resolve potential problems, extending equipment life, and reducing unplanned downtime.

How should I choose a power supply for extreme environments?

Choose power modules that resist high temperatures and have protection ratings (like IP rating). Consider components designed to withstand vibrations and shocks.

What are the benefits of a backup power supply?

A backup power supply prevents downtime by providing power in case of a primary failure. This is essential for mission-critical applications.

8. Conclusion

Ensuring the reliability and stability of your robotic power supply is fundamental. It is essential for achieving optimal performance, safety, and longevity. By choosing a power supply customized for your application, and focusing on voltage stability, overload protection, and thermal management, you support the operational consistency and accuracy of your robot.

As robotics advances, investing in quality power supplies remains a core component of an efficient and reliable robotic system.