We help the world since 2012

Modular Power Modules: Types, Applications, and Benefits

What’s a Power Module ?

Power modules are power supplies that can be mounted directly onto a printed circuit board and feature integrated power module for application-specific integrated circuits (ASICs), digital signal processors (DSPs), microprocessors, memories, field-programmable gate arrays (FPGAs), and other digital or analog loads. Generally, these modules are referred to as point-of-load (POL) power supply systems or point-of-use power supply systems (PUPS).

Because of the many advantages of modular construction, modular power supplies are widely used in switching equipment, access equipment, mobile communications, microwave communications, and communications such as optical transmission, routers, and in automotive electronics, aerospace and other applications.

Why Modular Power Modules Matter in Modern Applications ?

With the development of society, especially the popularity of Artificial Intelligence (AI) and smart devices, modular power modules have become an indispensable electronic component in the industries of robotics, communications, electric power, photovoltaic power generation, unmanned aerial vehicle (UAV), medical equipment, and space technology.

Driven by the rapid development of computer technology, mankind has entered the information society, which has also brought about the rapid progress of modular power solutions technology. For example, the increasing demand for miniaturization in modern communications equipment has directly contributed to the need for power modules to reduce size and increase power density, while improving efficiency to meet the requirements of complex systems.

Many industries, such as telecom, datacom, and wireless network systems, are adopting distributed power architectures to provide stable power. These complex systems require sophisticated power management solutions that can monitor and adjust parameters in real time to ensure that equipment is always operating under optimal conditions. To achieve this level of performance, designers often use high-tech components such as FPGAs, microprocessors and microcontrollers.

The widespread use of modular power supplies can be summarized by the phrase: “Where there’s electronics, there’s modular power.” Its stability, reliability and high efficiency make it one of the core components that quietly supports all electronic devices behind the scenes. Whether it is to provide power for intelligent robots or to guarantee stable operation for medical equipment, modular power supply modules are the first choice of engineers and product designers.

So, more than just a power supply, modular power supplies are an indispensable source of power behind modern technology.

Types of Modular Power Modules

There are two types of modular power supplies: fully modular and semi-modular.

Categories and Comparision

Fully Modular Power Supply

Definition: All cable connections are removable, allowing the user to connect and disconnect cables as needed.

Pros:

Increases flexibility in cable management and reduces clutter in the chassis.

Easy to replace and upgrade.

Better airflow and cooling performance.

Applications: For high-performance gaming consoles, workstations and systems requiring customized cabling.

Semi-Modular Power Supply (Semi-Modular Power Supply)

Definition: Only certain cables are removable, usually the primary connections (such as mains and CPU power), while other cables (such as SATA and PCIe) are fixed.

Pros:

Lower cost for those on a budget.

Still offers better cable management.

Applicable occasions: Suitable for medium performance computers, or where users want to strike a balance between price and flexibility.

Principle of Operation

Basic structure: The modular power supply consists of a main power unit, detachable cables and interfaces. The main unit is responsible for converting AC power to DC power.

Working mechanism:

AC input: the power supply receives AC power from the socket.

Conversion: Internal circuitry converts the AC power to the various DC voltages required (e.g. +3.3V, +5V, +12V).

Distribution: The current is distributed to the various components (e.g. motherboard, graphics card, hard disk, etc.) via detachable cables.

Advantage: This structure not only improves the efficiency of the power supply, but also helps to achieve better heat dissipation and reduce noise.

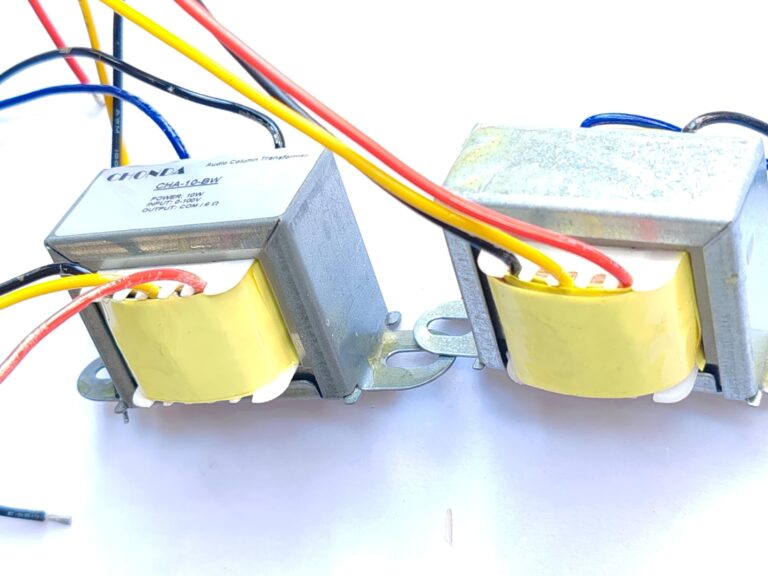

CHONDA TECHNOLOGY products such as the 10-150W TDC series are part of the Semi-Modular Power Supply

10W ~ 150W Smart Dc to DC converter for a Small Drone

feature isolated and regulated single-output with an efficiency of up to 90%. These modules offer a high isolation voltage of 1500VDC and can operate in a wide temperature range from -40℃ to +85℃.

Additionally, they include input undervoltage protection, as well as output overvoltage, overcurrent, and short circuit protection. Widely used in robotics, drones, railway equipment, medical devices, industrial control, power systems, and telecommunications, these DC-DC power modules ensure reliable performance in demanding applications.

Applications of Modular Power Modules in Various Industries

Robotics

Modular power modules provide precise voltage regulation and energy management, enhancing the efficiency and longevity of robotic systems. This is especially important in applications like automation and industrial robotics, where reliable power is crucial.

Telecommunications

In the telecommunications industry, these modules ensure stable power supply, facilitating the continuous operation of communication devices. Their modular design allows for easy upgrades. Their modular design allows for easy upgrades and maintenance.

Industrial Automation: Modular power solutions are highly adaptable.

Modular power solutions are highly adaptable, meeting diverse power demands across various equipment in industrial settings. optimize energy use and reduce operational costs.

Renewable Energy Systems

In solar and wind energy applications, modular power modules manage power distribution effectively, ensuring a reliable energy supply. They play a vital role in enhancing the efficiency and reliability of renewable energy systems.

Medical Devices

In the healthcare sector, modular power modules manage power distribution effectively, ensuring a reliable energy supply.

In the healthcare sector, modular power supplies ensure the reliable operation of medical equipment, contributing to patient safety and device performance. They can also be customized to meet specific power requirements for different medical applications

Key Benefits of Using Modular Power Modules

Flexibility: Modular power modules allow customization to meet specific power needs, making them adaptable across various applications.

Scalability: They can be easily scaled up or down, accommodating changing power requirements without the need for complete system replacements.

Improved Efficiency: These modules often feature advanced energy management capabilities, enhancing overall system efficiency and performance.

Reduced Downtime: Modular designs simplify maintenance and upgrades, minimizing system downtime during service or component replacement.

Cost-Effectiveness: The ability to replace only necessary modules can reduce costs compared to replacing entire systems, offering a more economical The ability to replace only necessary modules can reduce costs compared to replacing entire systems, offering a more economical long-term solution.

Key Considerations for Choosing a Modular Power Module

Power and Voltage Range: Select modules based on specific power and voltage requirements for optimal performance.

Stability and Reliability: Ensure the module’s reliability by checking performance metrics and user reviews.

Efficiency and Energy Consumption: Prioritize high-efficiency models to reduce energy costs and heat generation.

Safety Standards: Verify compliance with safety certifications to prevent accidents during operation.

Operating Frequency: Higher frequencies generally reduce noise but may increase costs due to more stringent material requirements.

Temperature Range: Choose modules suitable for your application’s environmental conditions, with options for commercial, industrial, or military- grade specifications. grade specifications.

Isolation Voltage: Higher isolation voltages enhance safety and reliability by minimizing leakage currents.

Additional Considerations

Form Factor: Consider the physical dimensions of the module to ensure it fits within your device’s design constraints.

Thermal Management: Assess thermal performance to avoid overheating issues, particularly in high-load applications.

These factors will help ensure you select the right modular power module for your specific needs, enhancing overall system performa.

We hope this article deepens your understanding of modular power supplies. As a manufacturer focused on modular power supply production for 12 years, we welcome your inquiries!