We help the world since 2012

Common Faults and Solutions for Power Modules

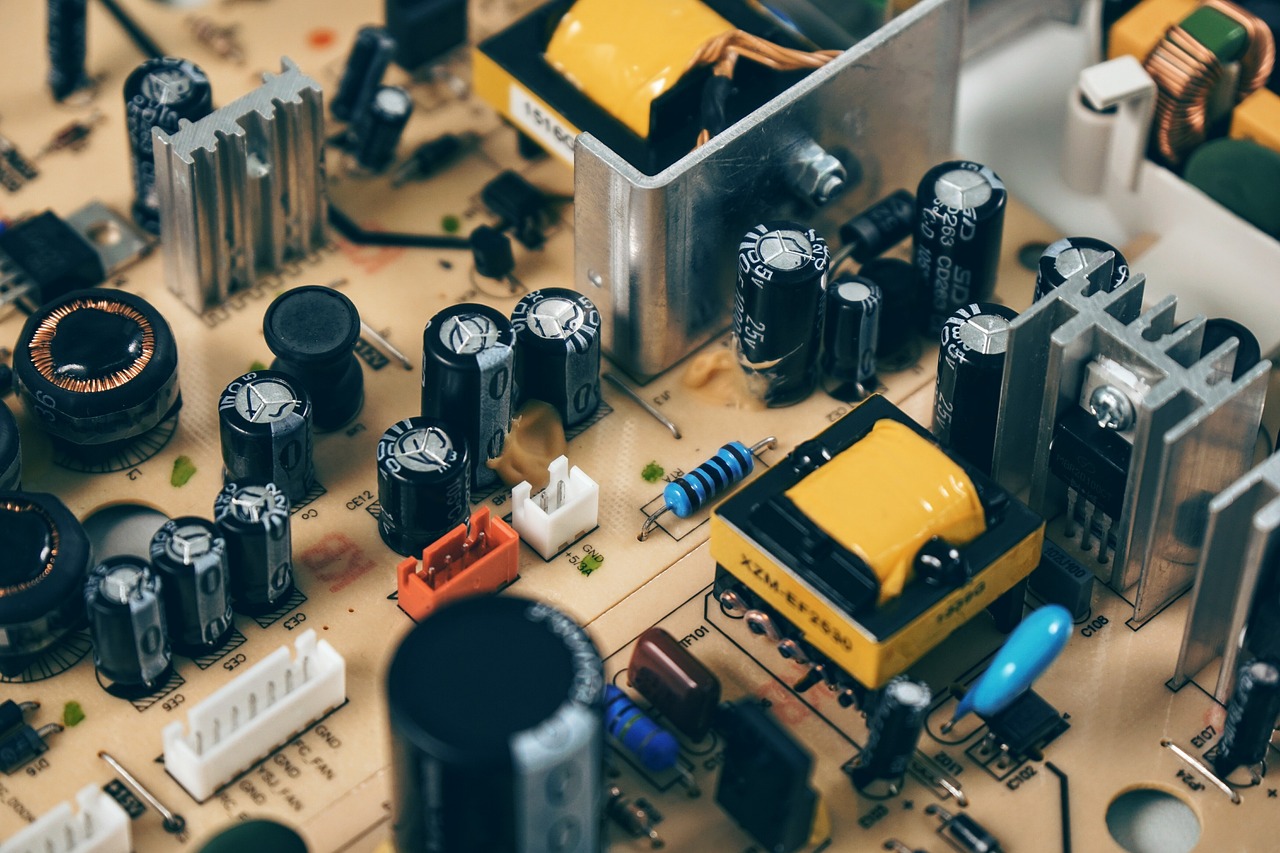

Power modules are the core components of modern electronic devices, akin to the “heart” of equipment, supplying stable power to integrated circuits, microprocessors, digital signal processors, and more. Their importance is undeniable: from complex industrial systems to the smart devices we use every day, all rely on the stable output of DC DC converter. Especially in high-tech fields like telecommunications, aerospace, and automotive electronics, power modules play a crucial role thanks to their efficiency and reliability.

However, with the increasing complexity of operating environments and diverse application scenarios, power modules are also facing various fault challenges. To help users better understand and address these issues, CHONDA TECHNOLOGY has conducted an in-depth analysis of common power module faults in the market and summarized solutions for frequently encountered problems. Below, we will share some of the common issues faced by power modules in actual applications and their corresponding solutions, hoping to provide useful guidance for your work.

1. Difficulty Starting the Power Module

One of the most frequent issues users face is difficulty in starting the power module or an inability to start it altogether. This is often seen when the module shows no response after powering on or takes too long to start. Although this issue may not be severe, it can still impact the normal operation of the entire system. While the module itself may not be damaged, startup difficulties are often related to some external factors.

Common causes:

- External capacitance is too large.

- Load current is too high.

- Excessive capacitive load.

- Insufficient input power.

Solutions:

- External capacitance too large: In this case, the power module requires more time to charge the external capacitor during startup, leading to a delay. Consider choosing a capacitor with an appropriate capacity to ensure that the load is within a reasonable range.

- Load current too high: If the load current exceeds the output capacity of the power module, startup will be affected. Reducing the load or opting for a more powerful module can effectively improve this issue.

- Capacitive load too high: When the capacitive load is too large, the power module may struggle to start. Adjusting the load or adding suitable inductance in series with the load can enhance startup performance.

- Insufficient input power: Insufficient input power can also hinder the normal startup of the module. Users are advised to check the input power and, if necessary, replace it with a more robust power source.

2. Overheating of the Power Module

Overheating during operation is another common issue with dc dc converter. During voltage conversion, a certain amount of energy is lost, which accumulates as heat inside the module. If the heat dissipation is poor, the rising temperature can severely impact the module’s normal operation and may even lead to failure.

Common causes:

- Using a linear power module with low efficiency.

- Load current too high.

- Load power too low.

- High ambient temperature or poor heat dissipation.

Solutions:

- Switch to a DC-DC converter: If you are using a linear power supply, it is recommended to switch to a more efficient DC-DC converter, reducing energy loss and thus lowering heat generation.

- Check the load current: A high load current can cause the power module to work under excessive strain, generating too much heat. Reducing the load or selecting a higher power-rated module can effectively alleviate overheating issues.

- Optimize heat dissipation: Ensure there is adequate space for heat dissipation, or consider using fans, heat sinks, or other cooling mechanisms. Effective heat dissipation is especially important in high-temperature environments.

3. Unstable Output Voltage

Unstable output voltage is another common fault in power modules, which not only affects the normal operation of the load but can also cause downstream device failures. This is particularly critical in scenarios that demand high voltage stability, where voltage fluctuations may cause serious system instability.

Common causes:

- Aging internal components.

- Significant load changes.

- Large input voltage fluctuations.

Solutions:

- Regular module inspection: Over time, electronic components inside the module may degrade, leading to unstable output voltage. Regular maintenance and timely replacement of aging components can effectively prevent such issues.

- Optimize load configuration: Large load variations can impact the stability of the power module. Maintaining the load within the rated range of the module can prevent voltage fluctuation problems.

- Add a voltage regulator: If the input voltage fluctuates significantly, it is recommended to install a voltage regulator to ensure input stability, thus maintaining stable output voltage from the module.

4. Excessive Output Noise

In some sensitive application scenarios, such as medical devices or communication equipment, the output noise of the power module can interfere with the normal operation of other equipment. This high-frequency noise or electromagnetic interference not only affects performance but can even cause equipment failure.

Common causes:

- Damaged filter capacitors.

- Poor design of the power module.

- Noise in the input power supply.

Solutions:

- Inspect and replace filter capacitors: Damaged filter capacitors can increase noise levels. Regular inspections and replacement of filter components can significantly reduce output noise.

- Optimize circuit design: Ensure that the power module has good electromagnetic compatibility (EMC) and employs appropriate shielding and filtering measures in its design.

- Use clean input power: The quality of the input power directly affects the output noise. Using a stable, noise-free power source can effectively reduce noise.

5. Rapid Burnout of the Power Module

A more serious fault is when the power module burns out quickly after powering on. This typically occurs in unstable electrical systems or when the power module is affected by external factors.

Common causes:

- Input voltage exceeds the module’s rated value.

- Internal circuit short circuits.

- Overload operation of the power module.

Solutions:

- Check input voltage: Ensure the input voltage is within the rated range of the module to prevent burnout due to overvoltage.

- Inspect for short circuits: Regularly check the module and its external connections to eliminate short-circuit issues. If a short circuit occurs, the module should be shut down immediately for repair.

- Avoid overload operation: Power modules should operate within their rated power range to prevent long-term overload that may lead to burnout.

6. Excessive Output Current from the Module

Excessive output current is another common fault. During operation, the power module may experience situations where the output current is too high, which can cause the module to overheat or even become damaged. In this case, an excessive current means that the load may be exceeding the module’s output capacity.

Possible causes:

- Load is too large.

- Output short circuit.

- Insufficient module power.

Solutions:

- Adjust the load: Ensure that the load is within the module’s rated current range to avoid overloading the module.

- Check for output short circuits: A short circuit at the output will cause a surge in current. Thoroughly inspect the wiring and fix any short circuits to effectively resolve this issue.

- Replace with a higher-power module: If the load consistently exceeds the module’s output capacity, it’s recommended to switch to a power module with a higher power rating.

7. Input Voltage Too High or Too Low

The last common issue is when the input voltage is either too high or too low—note that this refers to the input voltage. Input voltage falling outside the rated range is a frequent cause of power module failures. When the input voltage is too high, the internal components of the module may become damaged. On the other hand, if the input voltage is too low, the module may fail to start properly or output unstable voltage.

Possible causes:

- Power supply fluctuations.

- Unstable electrical grid.

- Incorrect input power selection.

Solutions:

- Use a voltage regulator: In cases of significant input voltage fluctuations, using a voltage regulator can effectively stabilize the power module’s input voltage, preventing faults caused by unstable voltage.

- Check the power quality: If the grid is unstable or the input power doesn’t meet requirements, promptly replacing or adding appropriate power supply equipment is a necessary measure to ensure the module operates correctly.

Conclusion

As a key component in electronic devices, the stability of power modules directly affects the normal operation of the entire system. By understanding and addressing common faults in a timely manner, you can ensure the continuous operation of your devices. CHONDA TECHNOLOGY has been focusing on the R&D and sales of power modules for over 12 years, adhering to the philosophy of quality first and service foremost, ensuring that we provide the best products and services to our customers. If you encounter any issues during use, please feel free to contact us.

Power modules are widely used in various fields such as railways, medical devices, drones, robotics, smart homes, and telecommunications. Let’s work together to ensure the stable operation of your equipment!