We help the world since 2012

The Ultimate Guide to Choosing a Robots DC-DC Converter

When working with robots DC-DC converter, understanding their importance is crucial for optimizing robotic systems. These converters play a key role in regulating voltage, which is vital for ensuring that various components of your robot receive stable power. In this comprehensive guide, we’ll explore how to choose the best DC-DC converter for robotics, key factors to consider, and real-world applications to help you make an informed decision.

But how do you choose the right DC-DC converter for robotics? There are so many options, and it can be overwhelming, especially if you’re not sure what to look for. In this guide, we’ll break down everything you need to know, so you can make an informed decision and ensure your robot performs at its best.

1. Why Do Robots Need DC-DC Converters?

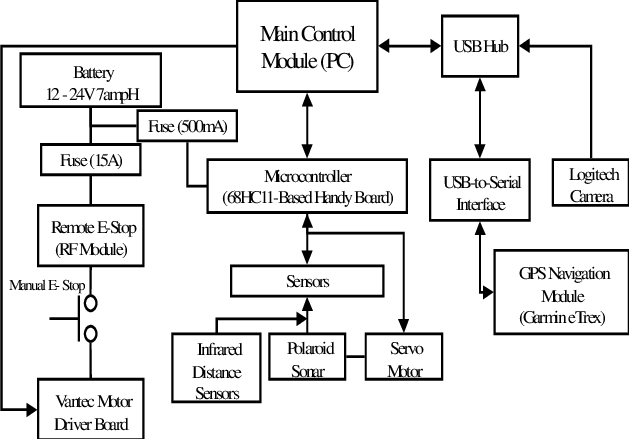

Robots DC-DC converters are essential for managing power distribution within robotic systems. They convert input voltage to the required output voltage, ensuring that each component of the robot gets the appropriate power. This is crucial for maintaining efficiency and preventing damage to sensitive electronics.

For instance, an autonomous robot may use a 24V battery but require different voltages for motors, sensors, and controllers. A reliable DC-DC converter ensures that each component operates smoothly and efficiently.

Robots operating in power-sensitive environments, like those powered by batteries, benefit immensely from efficient DC-DC converters. They extend operational time by minimizing energy loss during power conversion. This is especially important for autonomous robots, which need to maximize every bit of energy.

2. Key Factors to Consider When Choosing a Robots DC-DC Converter

To select the right DC-DC converter for robotics, consider the following factors:

a. Input and Output Voltage

Ensure the converter matches the voltage requirements of your robot. Whether you need to step down from 48V to 12V or 5V, the converter must handle these specifications efficiently.

b. Size and Weight

Space is often at a premium in robotics design. Whether you’re building a mobile robot or a robotic arm, the size and weight of your components matter. Compact DC-DC converters are highly desirable because they don’t take up much room and don’t add unnecessary weight, which can affect a robot’s movement.

c. Efficiency

Robots that run on battery power need converters that are highly efficient. An efficient converter ensures that less energy is lost during the conversion process, meaning your robot can run longer without needing to recharge. Look for converters with efficiency ratings of 90% or higher to minimize energy waste.

d. Thermal Performance

Since robots often work in challenging environments, such as factories or outdoors, thermal management becomes crucial. DC-DC converters that overheat can reduce the robot’s lifespan or cause operational failures. Therefore, opt for converters designed with robust thermal performance, ensuring they can handle the heat without affecting performance.

3. Types of Robots That Use DC-DC Converters

Different types of robots have unique power needs. Let’s explore some of the most common ones that rely on DC-DC converters:

Industrial Robots

Industrial robots are used for manufacturing, welding, and other heavy-duty tasks. These robots demand stable, reliable power to function efficiently for long periods. A high-quality DC-DC converter helps maintain consistent power delivery, ensuring that the robot operates smoothly even in demanding environments.

Service Robots

Service robots, used in healthcare, cleaning, or customer service roles, also need efficient power management. DC-DC converters in these robots help balance the power supply to the sensors, processors, and communication devices, ensuring continuous operation without interruptions.

Autonomous Mobile Robots (AMRs)

Autonomous mobile robots need power solutions that maximize battery life. DC-DC converters for AMRs are often compact and efficient, helping the robot stay mobile for extended periods without requiring frequent recharges.

4. How to Choose the Right Robot DC-DC Converter ?

Choosing the right converter may seem complicated, but it doesn’t have to be. Here’s a simple guide to help you make the best decision:

a. Power Requirements

Start by assessing your robot’s overall power needs. What are the voltage and current requirements for the different components? For example, if your robot uses a 24V motor but also has a 5V control system, you’ll need a DC-DC converter that can step down the voltage efficiently.

b. Voltage Regulation

Ensure that the converter provides stable voltage regulation. Fluctuations in voltage can cause sensitive parts of your robot, like sensors or microcontrollers, to malfunction. A reliable converter will keep the output voltage steady, even if the input voltage fluctuates.

c. Environment

Consider the environment in which your robot will operate. If it’s an industrial robot working in high-temperature areas, or a mobile robot navigating outdoor spaces, you’ll want a DC-DC converter that can withstand extreme conditions, such as dust, moisture, and temperature fluctuations.

d. Custom Solutions

Sometimes, off-the-shelf converters don’t meet all your needs. In such cases, a custom DC-DC converter might be the answer. For instance, if your robot has specific space constraints or unique power requirements, custom converters can be tailored to fit perfectly into your design.

5. Real-World Examples of Robot DC-DC Converters

Let’s take a look at some real-world applications of DC-DC converters in robotics:

Case Study 1: Autonomous Warehouse Robots

A large e-commerce company implemented a fleet of autonomous robots in their warehouses. These robots needed a DC-DC converter that could convert 48V battery power into 12V and 5V for sensors and communication systems. The chosen converter was compact and highly efficient, allowing the robots to work for longer periods between charges, ultimately improving operational efficiency.

Case Study 2: Industrial Welding Robots

An industrial welding company used robotic arms in their production lines. These robots required stable power to perform precision tasks. By integrating a robot DC-DC converter, the company was able to maintain steady voltage, even in high-temperature conditions, preventing performance issues caused by power fluctuations.

Conclusion

Choosing the right DC-DC converter for your robot can make all the difference in its performance, reliability, and efficiency. Whether you’re working with industrial robots, autonomous mobile robots, or service robots, understanding your power requirements and matching them with the right converter is key. Keep in mind the factors we discussed—efficiency, voltage regulation, size, and environment—and you’ll be on the right path to ensuring your robot runs at its best.

By investing time in selecting the right DC-DC converter, you’re not only optimizing the performance of your robot but also extending its operational lifespan. So, take a moment, assess your needs, and make a smart choice for your robotic project.