We help the world since 2012

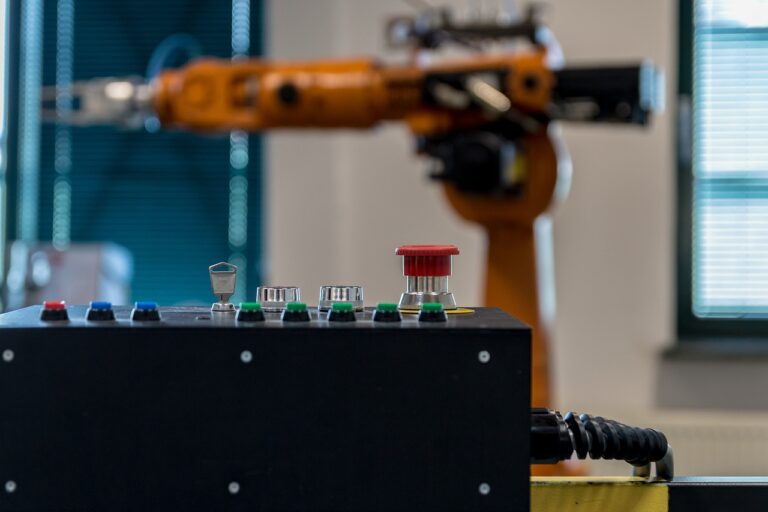

Tracked Robots in Harsh Environments and Their Power Module Requirements

1. What is a tracked robot?

Tracked robot, mainly refers to robots equipped with a crawler chassis mechanism.

Crawler mobile robots have the advantages of high traction, not easy to slip, good off-road performance, etc. They can carry cameras, detectors and other equipment instead of human beings to engage in some dangerous work (e.g., explosives removal, chemical detection, etc.) to reduce unnecessary casualties.

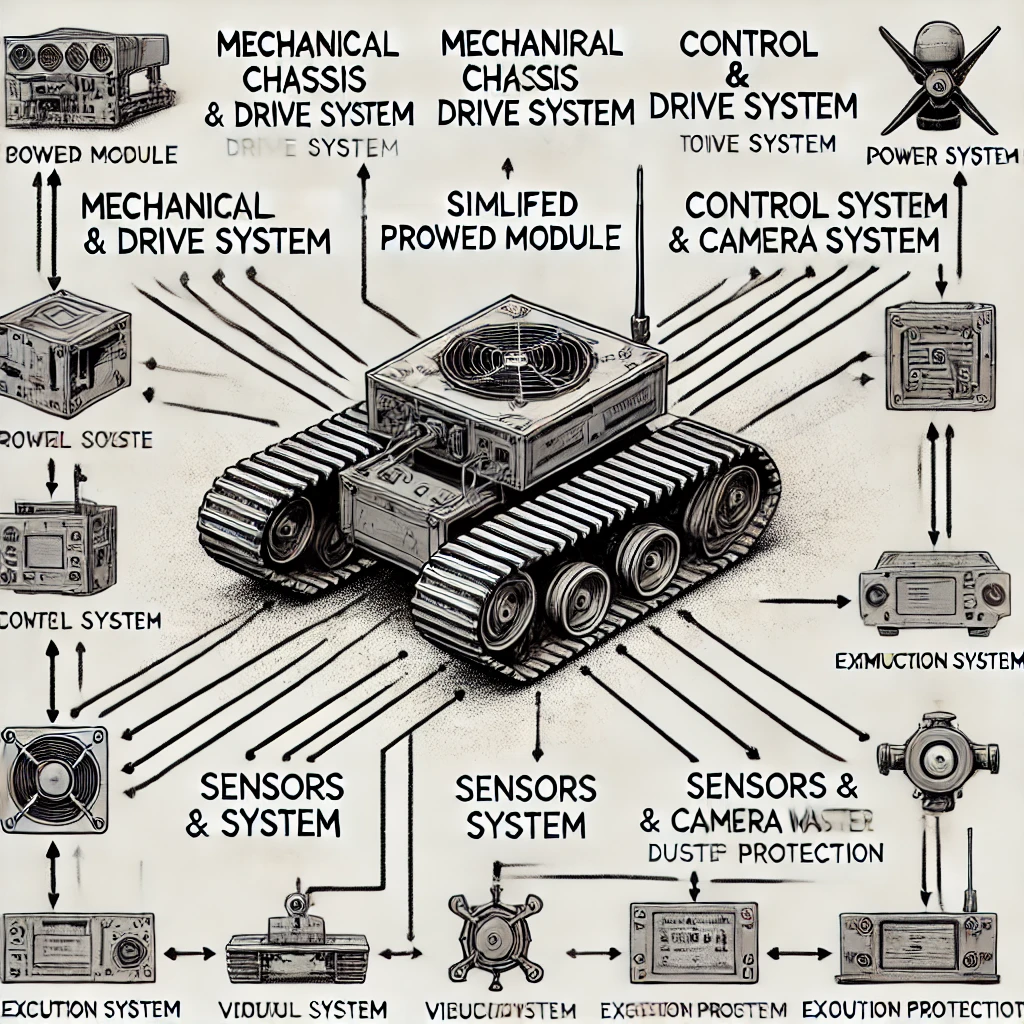

2. Tracked Robots Classification and Working Chart

The current tracked robots mainly include:

Military robots, such as explosive detonation robots, anti-terrorism robots;

Civilian robots, such as firefighting robots, rescue robots, patrol robots.

3. Important applications of tracked robots in harsh environments

Crawler robots are widely used in areas where high mobility and ruggedness are required, especially in extreme or harsh environments. Below are a few key application areas:

Military use

Tracked robots are commonly used for tasks such as mine detection, explosive ordnance disposal and battlefield reconnaissance. These robots must be able to work stably in complex terrain such as uneven, muddy or gravelly terrain, while being highly resistant to the temperature, shock and vibration of the external environment.

Rescue tasks

In natural disasters or emergencies, such as debris searches after earthquakes and flood rescues, tracked robots are able to traverse destroyed buildings, piles of rubble, and even water to help search for missing persons, transport supplies, and even perform dangerous exploration tasks.

Exploration and Archaeology

Crawler robots are also used for exploration missions in extreme geographic environments, such as craters, deserts, and glaciers. These environments require robots to maintain strong off-road capabilities and be able to operate properly in high or low temperatures.

4. Tracked Robot Power Module requirements in harsh environments

The nature of the task of tracked robots determines that their power module requirements are exceptionally harsh. The following are the core characteristics of power modules for these application scenarios:

High and low temperature resistance: When tracked robots work in deserts, polar regions and other environments, power modules must be able to maintain normal operation at extreme temperatures. This requires power modules with a wide temperature operating range, typically from -40°C to +85°C and beyond.

Shock and vibration resistance: In military applications and rescue missions, tracked robots are exposed to strong shocks and vibrations. Power modules need to be mechanically strong and reliable, able to withstand constant shock and vibration without damage and with stable performance.

Waterproof and dustproof design: In rescue and expedition scenarios, tracked robots may come into contact with substances such as water, mud or sand. Power modules need to have a high level of protection (e.g. IP67 or IP68) to prevent water and dust from entering, ensuring that the device remains reliable in wet or waterlogged environments.

CHONDA’s Tracked Robot Power Module Recommendations

To meet the power needs of tracked robots in extreme environments, CHONDA has launched a series of high-performance DC-DC tracked power modules that are particularly suitable for such application scenarios:

Wide temperature range power modules: CHONDA‘s DC-DC converter for robotics can operate stably in extreme temperature environments, ensuring that tracked robots can fulfill their tasks in both hot deserts and cold polar regions.

Rugged shock and vibration resistant design: By adopting a ruggedized housing and built-in anti-vibration design, these power modules are able to withstand all kinds of shocks and vibrations in harsh environments and maintain a stable power output.

High protection level: Some of our power modules meet IP67 and above protection standards, with excellent waterproof and dustproof capabilities, which can guarantee the robot’s long working hours in harsh environments.

Ending

Crawler robots are increasingly used in harsh environments such as military, rescue and exploration, and their agricultural robot power solutions are becoming more and more demanding. chonda’s high-performance power supply modules perfectly meet these special needs with their excellent high temperature resistance, shock resistance, waterproof and dustproof performance.

We are committed to providing efficient and reliable power systems for agricultural robotics to help them accomplish their tasks in the toughest environments.We are committed to providing efficient and reliable power support for robots to help them accomplish their tasks in the toughest environments.

At CHONDATECH, we offer a range of products designed for efficiency and reliability. Our main offerings include:

- AC to DC POWER MODULES

- DC to DC POWER MODULES

- Transformers

- The other electrical components

These products are engineered with sleek designs and optimized performance, attracting attention and earning appreciation from users across various sectors. Whether for personal devices or industrial applications, CHONDATECH converters and inverters are widely used in a variety of systems requiring AC or DC power, such as mobile phones, laptops, audio devices, automotive lighting, and more.