We help the world since 2012

Comprehensive robot power solutions: what you need to know

Robotic power solutions are becoming increasingly important in the context of modern automation and smart manufacturing. As technology continues to advance, robots are increasingly being used in a wide range of industries, and an efficient and reliable power supply system is key to ensuring their proper operation.

In this article, CHONDA TECHNOLOGY will take an in-depth look at the different power module options and how to provide customized solutions for specific needs.

1. Understanding Robotic Power Solutions

1.1 Definition and Importance

Robotic power solutions are the technologies and products that provide the power needed for various robotic systems. These solutions include not only power modules, but also controllers, sensors, and other related components. Effective power solutions can improve robot performance, extend its lifespan, and reduce maintenance costs.

1.2 Key Components

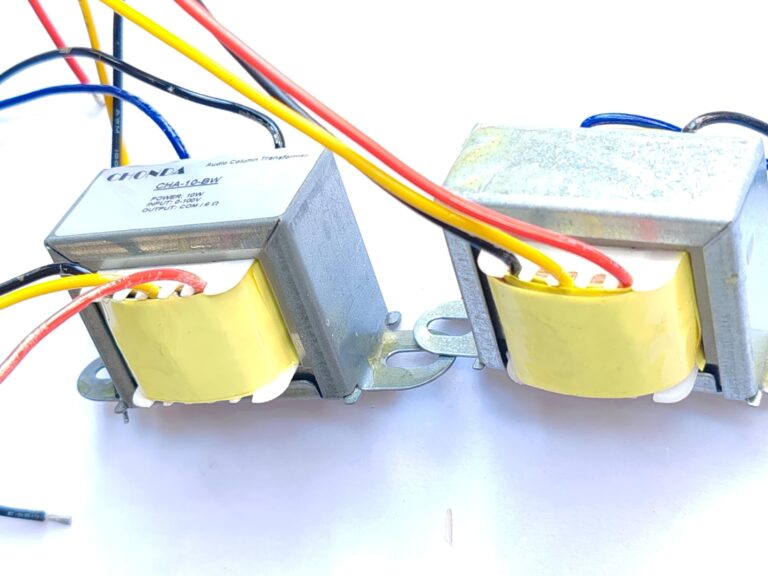

Power modules are a critical component in a complete robotic system. They are responsible for converting the input voltage to the appropriate operating voltage for the robot, ensuring stable operation of the various components.

2. Robot Power Module Options

2.1 Power Module Types

Understanding the different types of power modules is essential when choosing the right power module option. There are an endless variety of modular power supplies on the market, but common types include the followings:

- DC-DC Converters: These modules are used to convert one DC voltage to another, and are suitable for battery-powered robots and small devices.DC-DC converters not only improve system efficiency, but also meet a wide range of power requirements, and play a key role especially in electric mobile robots and portable devices. CHONDA TECHNOLOGY‘s 10-150W DC -DC power supply modules focus on serving robotic devices.

- AC-DC Power Supplies: This type of power supply converts alternating current (AC) to direct current (DC) and is widely used in equipment that requires a stable power supply. They are commonly used for industrial robots and heavy equipment, which often require high power output.

- Battery management systems: These modules are used to monitor and manage a robot’s energy usage to ensure safety and efficiency.

2.2 Efficiency and performance

Choosing a high-efficiency power module is critical to the overall performance of the robot. An efficient power supply module reduces energy loss and improves the robot’s range, thus increasing productivity.

2.3 Power supply selection guide

The following steps can be followed when selecting the right power solution:

- Determine power requirements: Calculate the total power consumption based on the power requirements of each component in the robot design (e.g., sensors, drive motors, etc.).

- Consider size and weight: Choosing a small and lightweight power module is especially important when space is limited.

- Evaluate efficiency: Selecting a high-efficiency power module reduces energy consumption and heat and extends battery life.

- Reliability and Stability: Ensure that the power module you choose can maintain stability in different operating environments, especially in high temperature or humid environments.

2.4 Choosing the right power module

There are several factors to consider when selecting a power module for a specific robotics application, including:

- Voltage requirements: Ensure that the selected module can meet the robot’s operating voltage requirements.

- Load capacity: Select a module with the appropriate power range for the robot’s power requirements.

- Determine power requirements: Calculate the total power consumption based on the power requirements of each component in the robot design (e.g., sensors, drive motors, etc.).

- Consider size and weight: With limited space, it is especially important to select power modules that are small and lightweight.

- Evaluate efficiency: Selecting a high-efficiency power module reduces energy consumption and heat and extends battery life.

- Reliability and Stability: Ensure that the selected power module can maintain stability in different operating environments, especially in high temperature or humid environments.

2.5 Power solutions for different applications

Robots in different fields have different needs for power solutions, take the following three common robots as an example:

- Industrial robots: High power and high stability power supplies are often required to ensure continuous operation in harsh environments. AC-DC power modules are a common choice for industrial robots, providing the required power and reliability.

- Medical robots: For medical equipment, the reliability and safety of the power supply is critical. Medical robots often use high-efficiency DC-DC converters to ensure that stable voltage and current are maintained over long periods of operation.

- Home service robots: such as floor sweeping robots, which are often battery-powered. DC-DC power modules can help adjust the battery voltage to suit the needs of different components and prolong the device’s runtime.

3. Customized Robot Solutions

3.1 A tailored approach

In many cases, standardized products will not meet the needs of a specific application, so a custom solution is required. By working closely with our customers to understand their specific needs, we can design a power system that is best suited to their operating environment and mission requirements.

3.2 Case Studies

For example, in an industrial automation project, we developed a specialized fixture for a customer that required a specific type of power supply support. By customizing the design, we managed to increase the efficiency of the equipment and reduce downtime.

3.3 Working with Engineers

Working with experienced engineers is an important step in developing an effective customized solution. They are able to provide expert advice tailored to the customer’s needs, ensuring that the system designed is both efficient and reliable.

4. Benefits of a comprehensive robotic power solution

4.1 Increased Efficiency

An integrated robotic power solution can significantly improve operational efficiency, making robots more stable and faster in performing their tasks.

4.2 Cost Savings

Organizations can realize significant cost savings through improved energy management and reduced downtime. This makes investing in an efficient power system a smart move.

4.3 Scalability and Flexibility

Customized solutions also provide scalability and flexibility, allowing companies to quickly adjust their production capabilities in response to changes in market demand.

5. Future trends in robotic power solutions

5.1 Emerging Technologies

As technology evolves, new robotic power solutions continue to emerge. For example, solid-state battery technology and intelligent energy management systems are emerging as future trends. These new technologies not only increase energy density, but also improve safety and reliability.

5.2 Impact on the industry

These trends will have a profound impact on various industries such as manufacturing, logistics and healthcare, enabling companies to utilize resources more efficiently and increase productivity.

6. Conclusion

Understanding the importance of robotic power solutions is essential for anyone looking to succeed in automation. By exploring the available options and considering customized solutions for specific needs, you can ensure that your robotic systems are optimized for performance, efficiency, and reliability.

Flexible power solutions are critical to the successful operation of your robotic system. By choosing the right AC-DC or DC-DC power module, you can not only improve the performance of your robot, but also extend its lifespan. When designing and realizing a robotics project, it is important to pay attention to power supply selection to ensure efficient and stable system operation.

If you would like to learn more about our robotic power solutions or inquire about related products, please feel free to contact us. We look forward to working with you to best support your project!